Your industry has unique challenges. Our focus on automation means we are distinctly qualified to provide solutions to address those challenges.

When you work with us, you engage a team of experts who have streamlined processes in a vast range of industries. From the plant floor to top management, we have improved processes throughout every stage of the manufacturing cycle. And we can do the same for you.

How? Through industry solutions that help you meet the critical need of integrating your factory from beginning to end, bridging islands of automation and carrying information throughout your plant — information that is essential to making better decisions and ultimately, increasing your profitability.

Automotive Industry

Automotive Industry

Reduce Your Time-To-Customer and Your Costs The automotive landscape is changing. Emerging markets are forcing you to re-think production strategies. The effects of a tight economy and intense competition means you need suppliers to play a larger role in successfully executing the supply chain. Our industrial automation and control solutions span the entire automotive supply chain and can help you address these challenges while staying focused on improving quality, reducing costs, increasing responsiveness and ultimately improving time-to-customer throughout your supply chain. By combining our integrated architecture with proven automotive manufacturing solutions, you get accurate, event-driven information about materials, operations and finished-product requirements — and the ability to deliver and receive the right components, in the right quantities, at exactly the right time and place. The result: faster time-to-customer for the entire industry. Your requirements are unique. So are our solutions. We listen to you then apply our resources to build cost-effective, results-based solutions for the automotive industry. We are committed to your success. Whatever your automation challenges, you'll find the answer by partnering with us.Automotive

Consumer Packaged Goods Industry Food

Beverage, Household, Personal Care & Chemicals Global markets, consumer diversity and environmental sustainability are key forces driving the evolution of the Consumer Packaged Goods (CPG) industry. Consolidation, changing consumer preferences, increasing government regulations, and energy and raw material costs, combined with the need for corporate and social responsibility, are dramatically impacting manufacturing strategies. In this dynamic and competitive marketplace, manufacturers must be prepared to offer a breadth of products to meet consumer demand. At the same time, they must consistently and cost-effectively meet quality standards for their products.Food and Beverage

Household, Personal Care & Chemicals Industry

Streamline Automation to Lower Production Costs, Increase Flexibility You have to meet cost, quality, flexibility and regulatory challenges across the entire life cycle — from raw materials through final shipment — and ultimately improve your time to market. Through our industry expertise we understand the pressures for consistent quality, validation, tracking and traceability — regardless of where your product is manufactured and distributed. We help you use automation technology as a competitive advantage — streamlining your manufacturing process and lowering production costs through flexible, open solutions that meet the constant challenges of new products and frequent changeovers, mix optimization, labeling and packaging, to name a few. In addition to comprehensive solutions that address every phase of your operation, you gain new control, visualization, networking, information management and regulatory compliance capabilities through Integrated Architecture — the only integrated control and information platform that runs discrete, motion, process and safety control. You get the right information in the right place, real-time, so you can make the right business decisions.Household and personal care

Life Sciences Industry

Your Partner for Life. Sciences. Faced with tumultuous times, Life Sciences companies are looking to partner strategically to succeed and grow. Rockwell Automation can be that partner. We have over 30 years of experience in the LS industry, a broad, integrated portfolio of manufacturing solutions, a global presence, and a dedication to our customers. From R&D through Clinical to Commercial Manufacturing, and from the control layer through a suite of information solutions and onward to the Enterprise level, we help you capture data and turn it into actionable knowledge.Life sciences

Water Wastewater Industry

Lower Your Project and Maintenance Costs Your customers evaluate water purification projects on initial capital costs and long-term operating costs. We can help you lower both. Reduce engineering time, cut installation costs and lower ongoing maintenance costs, all while getting the information you need, when you need it, through Rockwell Automation Integrated Architecture — the only integrated control and information platform that runs discrete, motion, process, drives and safety control. It's a single, coordinated control infrastructure for all your industry automation applications. Since reliability is paramount to your customers, you can ensure reliable system operation through support services that predict, prevent and react to operation problems — before they cause downtime. Our proven industry expertise means that you receive products and services that conform to stringent industry requirements, and produce real energy savings and greater control so you can demonstrate payback and minimize risk to the utility and your served community.Water / Wastewater

Mining, Minerals & Cement

Optimize Your Operation Globalization, heightened competition, higher production requirements and increasingly stringent environmental standards are placing enormous pressure on you to optimize your operation. Through our industry expertise we can help you meet these challenges, turn your automation technology into a competitive advantage and: ↣ Reduce your energy costs through advanced regulatory control. ↣ Increase uptime through power and automation components that feature built-in device-level diagnostics and communications. ↣ Increase production rates through integrating information, automation and power systems with Integrated Architecture — the only integrated control and information platform that runs discrete, motion, process and safety control so you get the right information in the right place, real-time. Expand your capacity and increase overall productivity with feature-rich products and rugged, reliable solutions designed for long-lasting service in the most severe industry environments.Mining / Metals / Cement

Oil & Gas Industry

Exceptional Performance and Value With today's changing market conditions, it's more important than ever to achieve exceptional performance while staying on schedule and within budget. Leading technologies and experience can help you reach these goals. Over the past 50 years, Rockwell Automation has accumulated extensive experience in the oil & gas industry giving us a keen appreciation of your issues and an in-depth understanding of the tools you need to address them. Utilize Exceptional Performance and Value through: Innovation — Increase your return on assets using cutting-edge technologies and solutions Project Excellence — Providing you low total cost solutions through a large team of specialists and technologies Sustainable Operations — Enhance safety, reliability and support environmental stewardshipOil and Gas

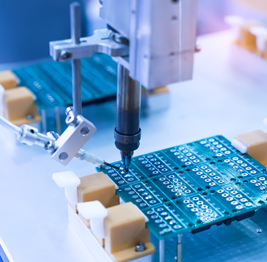

Semiconductor and Electronics Industry

Increase Manufacturing Effectiveness and Productivity With demand in the semiconductor industry for low-cost, high-volume, flexible manufacturing, you need leading-edge automation and information technology solutions that help your customers meet their business and technical goals. To be competitive, you need solutions for both FAB/Facility and Equipment/Material Handling applications that reduce risk, lower costs, and advance technology. Rockwell Automation Integrated Architecture has helped semiconductor manufacturers reduce their total cost of ownership by using a single automation infrastructure for their entire range of equipment and manufacturing applications: Design — Increase speed to market and engineering reuse by utilizing open, standards-based automation architecture and programming environment. Install — Faster installs and commissioning to specification from an integrated hardware, control software and networked environment. Operate — Increased up-time, OEE, yield and availability with field proven, robust, information enabled hardware, control software and diagnostic solutions. Maintain — Global support, locally, so you can maintain your automation investment at the lowest cost.Semiconductor / Electronic